The so-called ‘’Fourth Industrial Revolution’’, more often referred to as Industry 4.0, is a business model in which new technologies are disrupting production and consumption models, by the hugely increased employment of Artificial Intelligence’s data and algorithms.

When the concept of Industry 4.0 was born, roughly ten years ago, it was used in reference to the ‘’smart factory’’, a place where production activities are transformed by process digitalisation as well as robotics and the use of sensors connected to the Internet (IoT). Such paradigm soon began to spread like wildfire across the whole manufacturing sector, obviously including textile production.

Digital transformation, which is crossing each different area of the economy, has necessarily hit Fashion Industry as well.

It is noteworthy that the use of those technologies in Fashion Industry isn’t limited to the industrial production, instead it is transforming the supplying chain itself, from logistic to retail, from marketing to product design.

The major fashion brands are always looking for ways to create added value for their products, increasing the demand of consumers and boosting profits. To do so, Artificial Intelligence is increasingly exploited. Online sales, for instance, can benefit from algorithms implemented for improving user experience of consumers, supported by Market Basket Analysis and other Predictive Analysis algorithms for maximising sales.

In such framework, in the last few years ‘’Fast Fashion’’ production models have been disruptively transformed traditional cycles of Fashion brands. By virtue of an integrated value creation chain, in which production is planned in real time according to retail stores data, these brands were able to break traditional cycles and earn a huge market share. At the same time, nevertheless, consumers preferences are extremely diverse, being increasingly interested in, for example, sustainability and brand added value, strictly related to intangible aspects of its products or services.

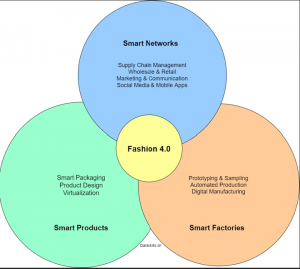

Hence the ‘’smart factory’’ concept is supported by ‘’smart network’’ and ‘’smart product’’, which should work together in building the future of Fashion Industry 4.0.

Each of these areas largely employs Artificial Intelligence technology.

Let’s see some:

Smart Factories

- Robotic automatization of production cycles

- Predictive algorithms for idenifying flaws

- IoT sensors for predictive maintenance of machinery

- Computer Vision systems for quality control

- Real time production processes monitoring systems

Smart Networks

- Predictive models for logistic management

- Predictive models for forecasting future demand

- Chatbots for helping internal staff in sales or marketing operations

- Chatbots for costumer service

- Routine Supply Chain Management tasks automatization

- Sentiment analysis and customer satisfaction tools for marketing purposes

- Predictive models, which integrate data from mobile devices, apps, social media, and e-commerce.

Smart Products

- Smart packaging for fighting against counterfeiting

- AI tools for designing products, analysing trends from web data or extracting cunsumers preferences

- “Digital showrooms” for letting consumers to try products before the purchase

- IoT sensors directly applied on clothing for connecting them to apps or additional services

Conclusions:

The availability of a huge volume of data, allowed some Fashion companies to modify their business by using Artificial Intelligence for introducing strategical innovation and improving their performance.

The challenge in the next few years will be to completely change the production paradigm and introduce advanced Analytics technologies in each phase of the production chain, in order to implement Fashion 4.0.

Sources:

Bertola, P. and Teunissen, J. (2018), “Fashion 4.0. Innovating fashion industry through digital transformation”, Research Journal of Textile and Apparel, Vol. 22 No. 4, pp. 352-369.

Giri, C. Jain, S. Zeng, X. and Bruniaux, P. (2019) “A Detailed Review of Artificial Intelligence Applied in the Fashion and Apparel Industry,” IEEE Access, vol. 7, pp. 95376-95396

Comments are closed.